Usually automation engineers want to use machine vision and AI in automation to improve test speed and accuracy. Speed up the production line and eliminate the need for manual inspection. However, there is a common misconception that implementing this technology is complex and requires high technical knowledge, requiring assistance from machine vision experts. Is that still true?

AI is now easier to use than ever with the advent of new technologies like Edge Leaning. Edge Learning is a subset of Ai, where the processing takes place either directly on the device or by using a set of pre-trained algorithms.

To optimize factory automation needs, the vision system uses Edge Learning technology to solve multiple applications quickly and easily. The system can be deployed within minutes and requires no deep learning and machine vision experience.

Anyone in the factory can set up Edge Learning, it's important to have product knowledge, not necessarily machine vision knowledge. If you understand what causes your parts to fail or what parts need to be sorted, then you will know all it takes to apply Edge Learning.

Exploring the full capabilities of In-Sight can take several hours. But learning how to use its basic abilities takes little time. An engineer can plug in the system, install a camera aimed at the part they want to test, take training photos, and produce useful results in less than ten minutes.

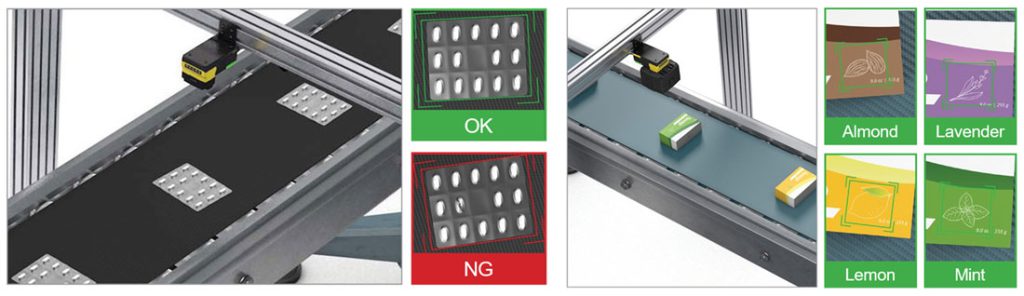

Classify is a useful classification process for parts for inspection purposes. During testing, those categories are usually OK/NG, separating pass parts from failing parts by detecting defects. Classification involves arranging finished products into multiple categories, such as different part variations or different configurations of a set containing many objects.

As an example of classification using Edge Learning technology, let's say your product is a container with a spoon to measure the contents. A box must have one and only one scoop included. As those containers travel down the conveyor, the scoops can be at various angles or partially obscured by the containers in the box.

Simply take three or four images of each condition with the In-Sight 2800, or you can upload an existing image, without spoon, one scoop, or more and mark which conditions pass and which do not. obtain. The In-Sight 2800 will make its own decisions about how to distinguish these, and the EasyBuilder interface will show how reliable it is for the classification.

If you misclassify one of the images, the confidence level will drop, so you need to run a deeper analysis to find the cause. Maybe you missed a scoop in the cans and labeled the picture as no spoon. Relabel that image as a one-spoon condition from which the confidence level rises again.

After training, the Insight 2800 will correctly classify each container. It can issue warnings, cache data, or send information down the line so that containers don't hit the redirect. It then provides you with a useful statistical breakdown for process improvement.

Using the In-Sight 2800 requires no specialized knowledge. The only knowledge required is the knowledge your resources have: what distinguishes the acceptable part from the unacceptable part, what category your product is, and when changing the product requires updating. In-Sight 2800 test and training update in short time.

So anyone working on your line or factory floor can use the In-Sight 2800 with just the few minutes it takes to get used to the interface.

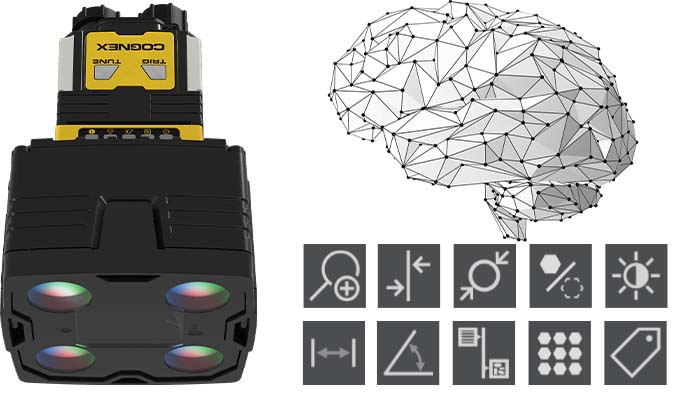

The In-Sight 2800 has everything you need to get up and running right out of the box. It includes a high-resolution sensor, fast processor, multicolored lighting, an option for high-speed liquid lenses, and an intuitive point-and-click interface. Other than that, all the systems need are power and data connections. It can be up and running in minutes, with its compact size designed to fit into even the most confined lines and spaces.

If you want to find the optimal solution for the factory process, make a difference and solve the problems that your business is facing, contact us - the supplier for the entire production process. your. New Ocean - đơn vị cung cấp giải pháp tự động hóa cho toàn bộ quy trình sản xuất của bạn.

>>> Xem thêm: HOW IS DEEP LEARNING APPLIED IN THE ELECTRONICS INDUSTRY?

----------------------------------------------------------

CONTACT INFORMATION

New Ocean Automation System Company Limited

Website: New Ocean Automation System

Hotline: 1900 0224