According to recently updated information, on April 12, 2025, the Central Executive Committee issued Resolution No. 60-NQ/TW, under which Vietnam’s 64 provinces and cities will be consolidated into 34 administrative units (28 provinces and 6 centrally governed cities). This is a significant step toward streamlining the administrative apparatus, but at the same time, it also poses various practical challenges for manufacturing businesses.

Because after the provincial mergers, seemingly minor details such as addresses on labels, barcodes, or QR codes can quickly become complex challenges. It’s no longer just about “reprinting correctly” — it’s now a race against time to update all packaging designs simultaneously, ensuring full legal compliance without disrupting the supply chain.

The changes in provincial names and administrative boundaries bring along various challenges for legal compliance and product identification. This is especially critical for businesses in sectors such as FMCG, pharmaceuticals, food, consumer goods, and electronics — where packaging and labeling must be absolutely accurate. For these industries, the major risk is:

The story becomes even more complex when a business operates multiple factories or works with various printing partners across different provinces. Each administrative change means hundreds or even thousands of packaging designs must be updated, reviewed, proofed, and reprinted — with the risk of errors at any stage.

While production must keep running smoothly, manually checking labels and packaging for errors is nearly impossible to guarantee absolute accuracy. So how can businesses control these seemingly minor but critically important changes?

Understanding the pressure manufacturers face, NOAS offers a dual solution that acts as a powerful ally to help businesses comprehensively control the printing inspection process and ensure that every printed package meets the highest accuracy standards.

New Ocean's Offline Artwork Inspection System is designed to compare the approved master artwork file (typically a PDF or Adobe Illustrator file) with the actual printed sample. This is a crucial pre-production step to detect printing errors such as color inconsistencies, dimension inaccuracies, multilingual text errors, smudges, ink bleeding, or stray marks — ensuring the final print perfectly matches the approved design.

Equipped with a high-resolution scanner and a computer vision algorithm (OpticalFlow), the system automatically compensates for material stretching and detects even the tiniest defects invisible to the naked eye, such as:

Additionally, the system generates detailed inspection reports to help QA and Marketing teams keep comprehensive records for internal approvals and fast auditing. During the “race” to update packaging according to new administrative boundaries, the Offline Artwork Inspection System is a powerful tool to “stop errors at the source.”

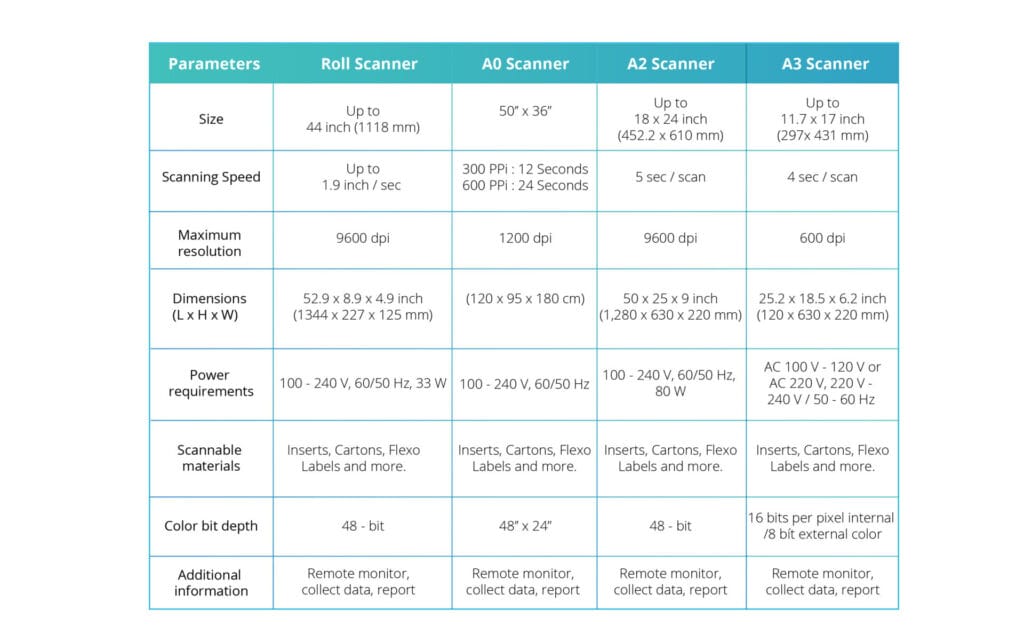

Specifications

If your business needs to inspect printing quality during production or on an independent line, the Inline Artwork Inspection System is the resonable choice.

This system uses high-resolution industrial cameras combined with computer vision and deep learning algorithms to detect complex defects that traditional image processing alone cannot identify. Its outstanding strength lies in its ability to verify content, color, and print positioning on every single product, helping you:

This solution is particularly suited for industries with strict printing quality requirements such as pharmaceuticals, food exports, cosmetics, and private label packaging.

Together, Offline & Inline Artwork Inspection Systems help businesses not only minimize misprints but also:

As Vietnam enters the phase of provincial mergers, manufacturing businesses are under increasing pressure to “change quickly yet accurately.” Looking on the bright side, this is also the perfect time for businesses to automate their entire print inspection process — a step that may seem minor but has a significant impact on the entire supply chain and customer trust.

With the Artwork Inspection System – Offline & Inline, NOAS offers cutting-edge print inspection technology and serves as a reliable partner, supporting businesses in their journey toward intelligent, agile, and highly precise transformation down to the smallest detail.

New Ocean Automation System Company Limited

Website: New Ocean Automation System

Hotline: 1900 0224