Is a useful solution for reading and checking the quality of printed or engraved barcodes on product packaging and surface through specialized equipment such as industrial cameras and software.

Relating to structural operational structure, barcodes printed on the product are scanned and identified through industrial cameras and fixed/ handheld scanners. Next, a read-and-process-images software decodes all data contained in the scanned barcode and transfers it to a connected computer. Thence, the software will analyze information, decode and provide corresponding data of products or goods that need to be checked accurately to ensure that these barcodes meet the set quality standards.

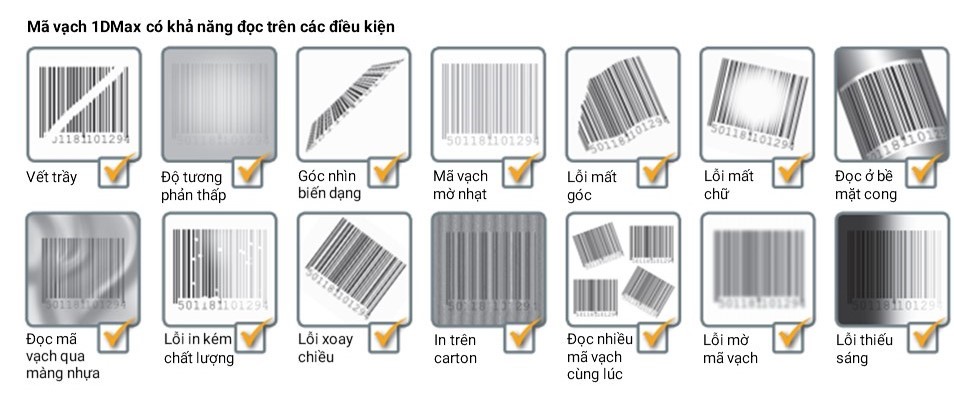

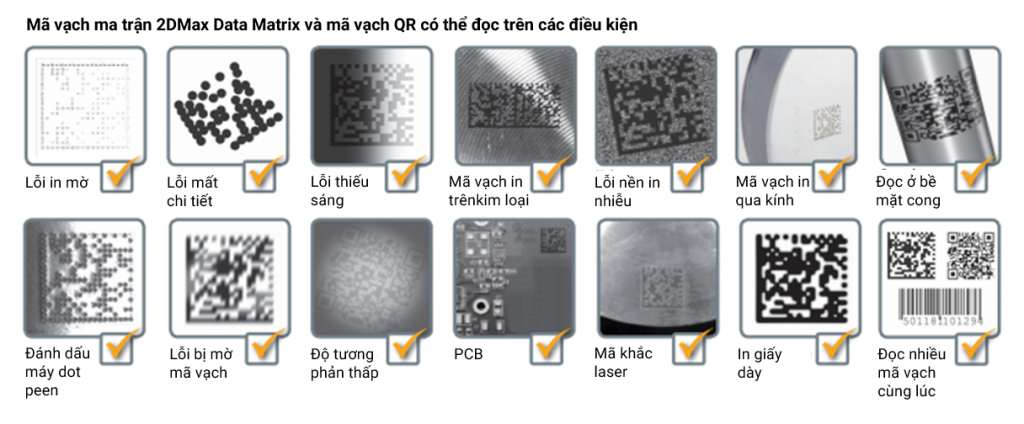

- The rate of industrial barcode reading is up to 99% accurate, applying on a variety of materials such as paper, iron box, bottle, carton, etc.

- Ability to check 1D / 2D barcode content of objects on all materials and surfaces.

- Ensuring data consistency throughout the production process.

- Ensuring high accuracy of barcode content.

- Quality inspection of 1D barcodes, 2D matrix codes and postcodes.

- Manage the process of inspection and tracking (track and trace) closely from mixing raw materials, filling to packaging.

- Cost-saving for management and labor.

- Flexible design which is suitable for all sizes of manufacturing plants, lighting conditions and production goals of each business via several 3D Vision Inspection solutions that New Ocean is providing below:

- The system reads magnetic barcodes using image processing technology. To read 1D/2D/DPM barcodes on high-speed production lines.

- Identify barcodes to be printed at any position/direction; identify

- Exclude poorly printed barcodes; and can read multiple barcodes at the same time. In case of wrong barcode detected, our system will report/warn to the operator immediately.

- Depending on your budget and current production conditions, our vision barcode system can use a variety of industrial cameras while ensuring barcode reading criteria.

- New Ocean's bar code identification and verification solution package are flexibly designed and suitable for lighting conditions, factory size and production goals of each business. The solution is integrated with hardware devices and software programs, pre-programmed and easy to use, fully satisfies the barcode quality inspection standards of each specific manufacturing industry.

- The product life is highly guaranteed going with 24/7 warranty and maintenance services from our highly-skilled engineers. Cooperating with us, not only You can be comfortable about the efficient and stable operation of the system, but also proactively control Your automatic technology at Your manufacturing plant.

- We support consulting, repairing and replacing new devices with reasonable costs, which could save Your Business’ labor costs and optimize production efficiency.