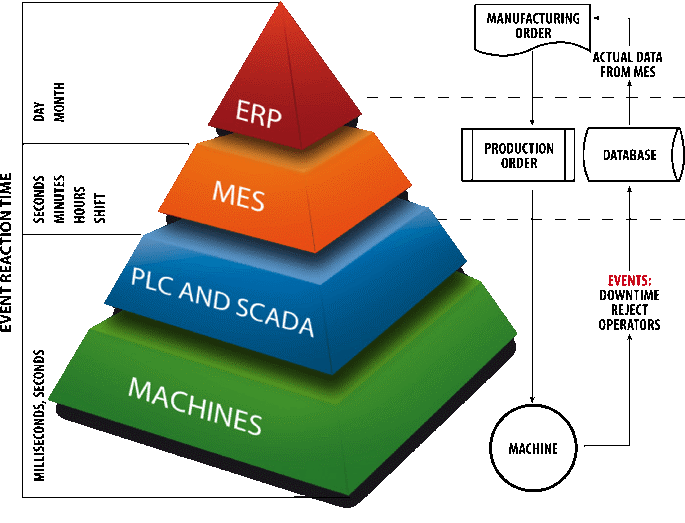

In strongly developing digital technology, Smart manufacturing solutions (Smart Manufacturing) implemented to increase efficiency in production. Defined as an intelligent orchestration system operating in real time (real-time orchestration).

Optimizing physical & digital production processes at the factory in particular and the entire supply chain in general. As a result, resources and processes are automated, integrated, and monitored. Continuously evaluated based on available information closest to real time!

An intelligent production line cannot function without a Manufacturing Execution System (MES) that coordinates operational functions. Additionally, MES analyzes key production metrics such as KPI and OEE.

MES can reduce the cost of operation of multiple production systems, standardize work systems and establish value-creating foundation through customers’ communication. Additionally, the system setup can flexibly respond to changes in the production process by applying the most modern IT technologies.

MES can increase management speed and productivity thanks to accurate information flow, facilitated by consolidating information and improving product quality through each production stage. Besides, the system also flexibly responds to changes in the business environment, at the same time gives accurate and quick decision information to promptly adjust the production process.

A complete MES system can give correct Just-In-Time decisions, plan and allocate materials in order to shorten production times as fast as possible.

A complete MES system can give correct Just-In-Time decisions, plan and allocate materials in order to shorten production times as fast as possible.

MES system can reduce time of batch record review as well as overhead costs following FDA and CGMP standards with 75% validation efficiency.

Investing a complete MES can improve competitiveness in the future.

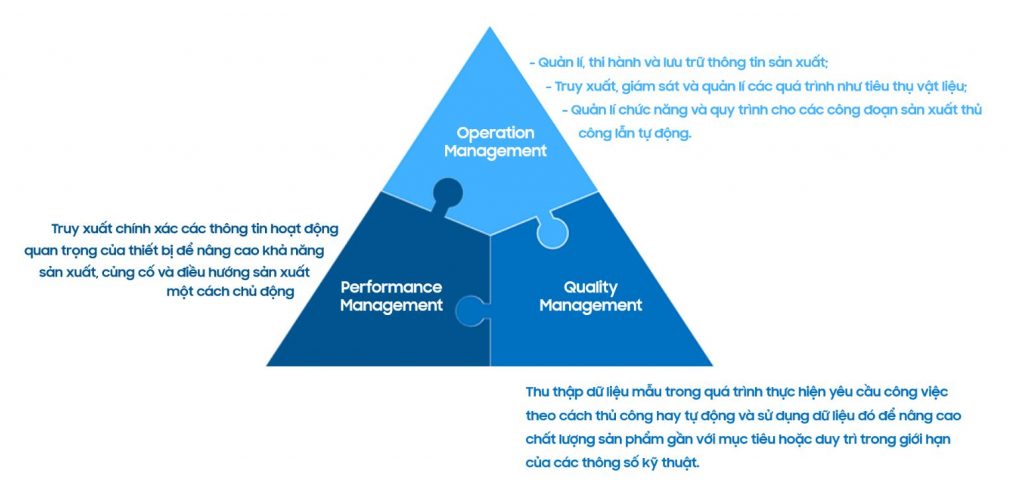

Our MES is structured based on 3 main functions: Operation Management - Performance Management - Quality Management

- To reduce production costs from optimizing production processes and work schedules with fastest delivery times.

- To increase profits by improving production, reducing excess materials and reproducing, helping to achieve better quality products.

- To ensure stability due to increased efficiency and ability to react to unexpected situations or product recall incidents.

- To increase consumer satisfaction by improving transparency in order fulfillment, correct paperwork, and reducing damage to output products.

- To reduce capital cost by identifying the most productive asset on a production line so production is not interrupted.

- To increase efficiency in using better equipment by quickly identifying ineffective steps.

- To increase the capabilities of existing equipment by pinpointing the exact causes of downtime to improve efficiency.

- To help compare performance between production lines, manufacturing plants including real-time OEE measurement.

- To automate the sample quality process directly from the plant's control system or machine system data. Hence to increase operational efficiency with accurate quality data and reduce quality costs.

- To flexibly manage sample quality for changing production schedule and required quantity of products according to specific orders, helping to increase operating speed while ensuring labor safety standards.

- Statistical Process Control (SPC) monitors sample data immediately accompanied by rule and violation restriction notifications. This helps increase product quality, reduce losses by maintaining tight control as well as a quick response to deviations.

- Being completely designed according to Your manufacturing plant’s requirements such as: shipment inspection, inventory/ work in progress, process management, data collection and analysis; suitable for large, medium and small production scale for each particular industry.

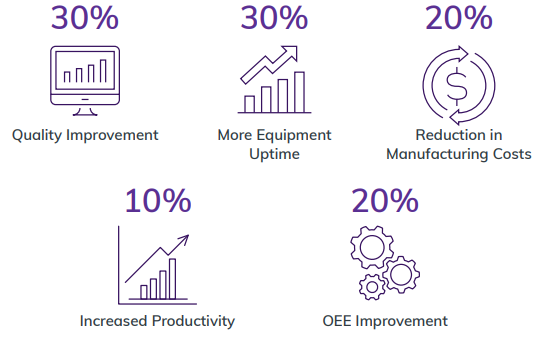

The next outstanding point is New Ocean's MES solution that can analyze work performance. Know the depreciation status of the machinery. From there, managers will easily grasp the production situation of the factory. Provide necessary strategies in upcoming production activities. New Ocean - The next outstanding point is New Ocean’s MES solution can analyze production efficiency and machine depreciation status. Hence, the managers will easily have an overview of their manufacturing plant’s production situation and give necessary strategies in upcoming production activities.

- Reasonable operation costs, minimizing H / W and S / W costs with the system structure optimizing production efficiency. A complete MES system will help payback in 12 to 24 months.

- The solutions have been proved and operated officially by several domestic and foreign manufacturing plants.

- Simplifying the UI/ OI design interface and standardized with complete information, easy to understand and get access via the web system. Real-time information is updated every second and able to get access whenever via the internet.

- We support consulting, repairing and replacing new devices with reasonable costs, which could save Your Business’ labor costs and optimize production efficiency.